The company moves from the centre of Stuttgart to the industrial district of (Bad) Cannstatt, where Gottlieb Daimler and Wilhelm Maybach have already developed the world’s first high-speed combustion engine.

1930 - 1939

Company history

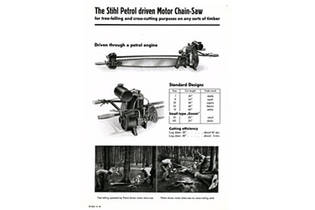

STIHL presents his portable petrol-powered chainsaw at the Leipzig trade fair – it is well received. The first exports go to Switzerland, the Netherlands, Belgium and France. STIHL enters into a business relationship with a foreign importer (Defries in Milan, Italy) for the first time.

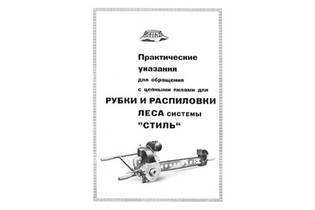

Andreas Stihl travels to the Soviet Union, where he receives an order for several hundred STIHL tree felling machines. Unlike most German companies, he does not have to dismiss anyone in spite of the deep economic crisis. Up to 26 machines per month are produced with a staff that has now reached 38.

Organisation and sales become more demanding as the company grows more successful. Andreas Stihl already has nine office staff at his machine factory.

STIHL trains the first apprentice mechanics. Skilled workers with outstanding qualifications form the backbone of the company, which consistently develops technical improvements and employs new models.

In the first profitable year since the global economic crisis, the employees reap the benefit of the first Christmas bonus in the company’s history. Sales of STIHL chainsaws increase around the world, as the rising industrial demand for wood and the wood product cellulose poses major challenges for forestry management and sawmills.

The new company logo reflects the close relationship of STIHL with the development of the chainsaw and the importance of its products in all areas of forestry and forest operations.

Andreas Stihl takes an extended sales trip through the US and Canada. With 27 models, the STIHL brand is already recognised worldwide as the epitome of modern chainsaws.

Product history

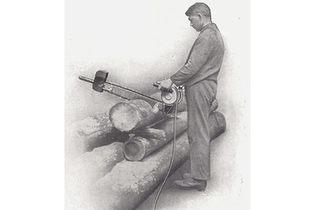

A new electric chainsaw for cutting to length is the first that can be operated by just one person. It is mainly used in log yards. The STIHL "Liliput", the successor model, comes to market in 1933 and weighs 25 kg.

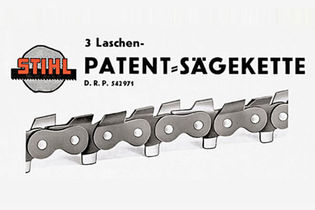

A. STIHL MASCHINENFABRIK in Stuttgart-Bad Cannstatt receives a patent in 1932 for the 3-lug saw chain with cutting teeth and rakers for better chip removal.

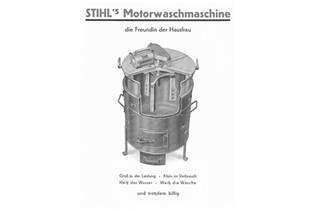

Washing machines with a choice of electric motor or water drive complement the chainsaw product segment for a few years.

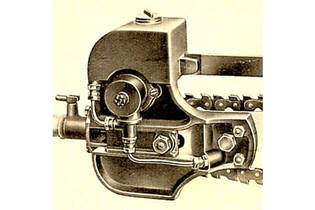

Pressure-feed lubrication in the hand piece oils the saw chain and guide bar as needed. The fully automatic “lubrication for saw chain machines” developed by Andreas Stihl, regulated for the first time by the rotation of the sprocket, receives utility patent protection from the patent office of the German Reich.

For decades, the non-jamming speciality saw and its successors are used to cut logs to length in log yards.

With the centrifugal clutch, the saw chain starts moving automatically as the motor rotation speed increases.

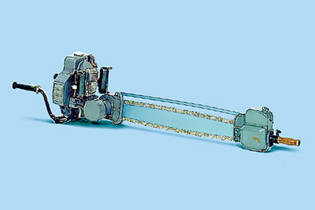

The compressed air chain saw with fully encased gear mechanism weighs only 14 kg and can be used in mining and even underwater.